LIGNA 2017: A POWERHOUSE OF WOODWORKING TECHNOLOGY

IN WHAT CAN ONLY BE DESCRIBED AS THE GREATEST WOODWORKING TRADE FAIR ON EARTH, LIGNA, HELD IN HANNOVER GERMANY FROM 22-26 MAY, WAS A POWERFUL DEMONSTRATION OF THE INEXORABLE MARCH OF SOPHISTICATION OF WHAT CAN BE ACHIEVED WITH WOOD. MICHAEL DOLPHIN REPORTS.

After five action-packed days, the organisers could look back on a truly impressive event.

“Ligna 2017 will go down as a milestone in the digitalisation of the wood industry,” said Dr. Andreas Gruchow, the Deutsche Messe Managing Board member in charge of Ligna, at the end-of-show press conference.

“The exhibitors covered everything from sophisticated approaches to plant integration right on down to entry-level systems for the skilled trades, thus offering the right technology for any scale of operation.”

More than 1,500 exhibitors, including 900 from abroad, were on hand to showcase innovative plant equipment, machinery, tools and solutions on some 129,000 square metres of space. According to Gruchow, “Many exhibitors have opted for stands with a highly classy design, in some cases even going for radically new structural approaches. This has put a fresh face on Ligna and gone down very well with all concerned.”

The event attracted a total of 93,000 visitors, including some 42,000 attendees from outside Germany who had come to Hannover from more than 100 countries. As noted by Gruchow, “These impressive figures confirm that international decision-makers have come to place their trust in Ligna as the only event that can give them a full grasp of the latest wood processing and woodworking trends and developments.”

On display were an impressive array of entry-level prefabrication machines that offer an affordable and flexible entry to manufacturers, either wanting to enter the offsite construction space or complement their existing suite of machinery.

Built Offsite visited these stands and here shares a sample of what’s available or may soon be available in the Australian market.

HOMAG / WEINMANN

With its debut at Ligna Homag / Weinmann offers an entry-level machine the WMS 060 can process wall elements, roof elements, floor or gable elements at extremely high precision, and its wide range of applications enables it to produce a wide variety of wall structures and materials quickly.

Tamara Brumm from Weinmann, confirmed that typically smaller companies tended to rely on a manual approach, as bigger machines were too expensive. Positioned at 105,000 Euros, the WMS 060 offers a lower cost alternative.

“We definitely see Australia and New Zealand as a market for such entry level solutions,” she said.

Several of its features include direct data entry on the machine utilising a recently developed software tool called easyRun, and this is achieved without any CAD files. However it’s also worth noting that it can also accept CAD files if required.

Other notable features of the WMS 060 machine include: Fully automated fastening of the different sheathing with two stapling or nailing devices; tracking and compensating thickness fluctuations in the element by means of a measuring routing unit; and it can be combined with various work tables. It can also be configured with other machines as part of a manufacturing line.

TECHNICAL SPECIFICATIONS

Max. working width (mm) 3.200

Min. working height (mm) 75Max.

working height (mm) 50

Processing length (m) customer-specific

www.homag.com/en/product-detail/multifunction-bridge-wms-060/

WEINIG

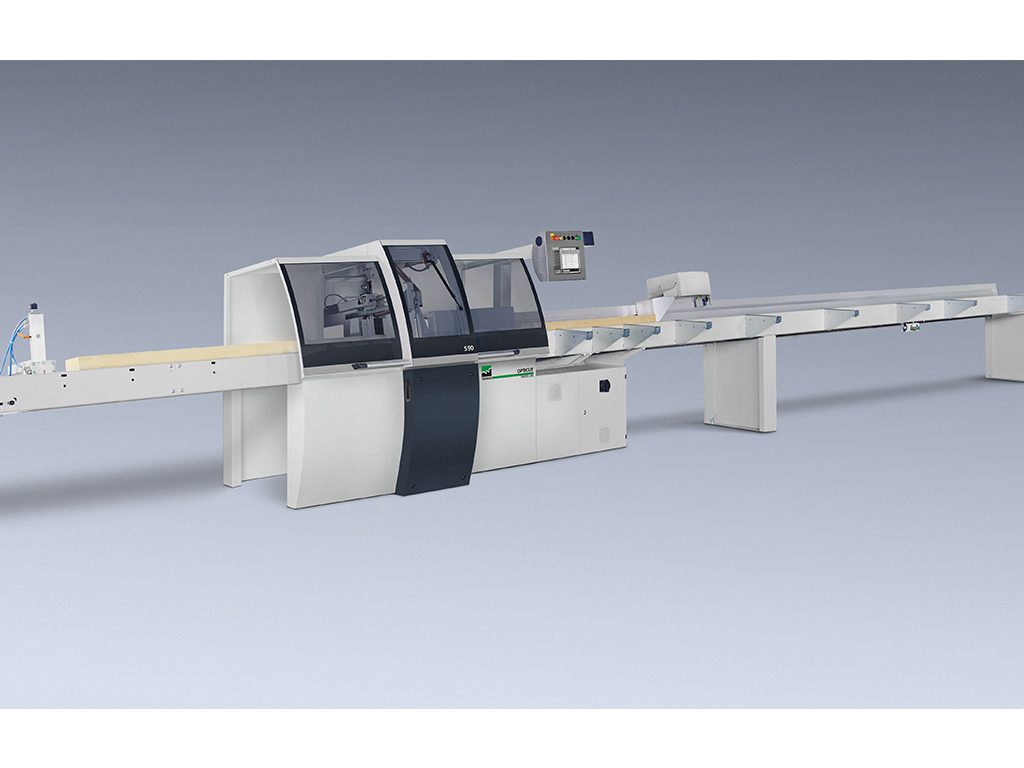

A machine that has a clear application from frame and truss manufacturers through to CLT (cross-laminated-timber) manufacturers is the OptiCut S 90 series from Weinig. Used for cross-cutting, it offers a high level of precision whether cutting single boards or packages of boards, profiles or rods in solid wood, panels or even plastics.

Neil Forbes (Managing Director Weinig Australia) says: “The OptiCut S 90 has been very successful in Australia and is ideal for rough sawn or dressed material and cutting out defects in timber. We have 12 clients in Australia who use the machine, and it feeds into a framing table, accepts lower value timber and more cutting sizes.” The centrepiece is the unit comprising the saw, positioning system, controls and software – everything from a single source. This enables the operator to fully automate the process stages of – transport, positioning, clamping and cross-cutting of a variety of in-feed materials.

The Dimter Line OptiCut S 90 series with its various options offers the ability to fully automate the cross-cutting process and to integrate additional work stages: charging, sorting, waste separation, stacking of single boards or package of boards, workpiece recognition as well as drilling and milling processing from a single source.

www.weinig.com.au

LEDINEK

This company was established over 50 years ago, when Managing Director Gregor Ledinek’s father started out as a barrel maker before moving his business into machines. It’s a striking evolution that now encompasses equipment capable of planing, profiling, finger jointing and producing engineered timber.

With a presence in over 25 countries, and represented by its New Zealand / Australian distributor (Skookum Technology Ltd), the company assisted in the supply of a complete CLT manufacturing plant in Albury-Wodonga for XLam which is due for completion in early 2018. Curvatures have always been a signature of the company, and Ledinek said: “There’s a lot of copying in the market but we innovate, and in Europe there is a high level of demand for CLT, so we definitely see this as a growth market.”

www.ledinek.com/

RANDEK

Offering a full product line of machines and systems for prefabricated house manufacturing, Randek’s offering can be broadly categorised into Cuts Saws, Wall/Floor/Roof Production Lines, Roof Truss Systems and Butterfly Tables. Based in Sweden, the company history dates back to the 1940s and it has delivered high performance woodworking machinery to house manufacturers in nearly 40 countries in four continents. Randek is represented in Australia by Bliss and Reels.

www.randek.com

L-R: Karl Hellstrom (Randek), Mikel Holm (Randek) and Jason Reints (Bliss and Reels).

ESSETRE

Augusto Fontana of Essetre Italy confirmed Asia, Australia, New Zealand and the UK were target expansion markets for the company. Founded in 1979 as a kitchen furniture machine production specialist, Essetre is a self-described pioneer in CNC machinery, with a 15 year track record in construction housing machinery.

“Our speciality is flexible machinery that can process many shapes. We have around seven models and a strong focus on customisation.”

On display at Ligna was the Techno Saw, an entry level machine for timber frame houses. “This machine can deal with CLT and also frames. It’s priced at around $180,000. We believe there is a lot of opportunity in Australia.”

www.essetre.com/en/

Augusto Fontana of Essetre, Italy.

BIESSE / UNITEAM

Italian manufacturing giant Biesse had the largest booth at over 5000 square metres, and has recently partnered with Uniteam (of Italy) who specialise in the design and manufacture of multi-axis CNC centres dedicated to machining beams of solid or laminated wood.

For over 20 years Uniteam has been present on the Italian and international markets, offering advanced and customised technology solutions to meet customers specific needs. Due for launch in Australia next year is the Uniteam CK processing centre which was on display and is ideally suited for medium and large industries that need flexibility in order to handle standard cuts used in woodwork but also capable of meeting the complex demands of modern design. Several of its (many) capabilities include a 5-axis machine control (bi -rotary head) through its Tool Centre Point (TCP), advanced algorithms for High Speed Cutting (HSC) and complete 3D roto-translation.Silvano Maddalon of Uniteam says: “Housing has seen CLT panels boom over the last 10 years in Europe and is also growing in the Asia Pacific and Australian markets. We can input complete projects and bring in every component, optimise and simulate programs in very short time for thousands of pieces. It’s very promising for the Australian market. We also have a service centre in Australia as well.”

www.biesse.com/au/biesse_products/uniteam

SCM

SCM’s history dates back to 1935, when Nicola Gemmani and Lanfranco Aureli, mechanical and foundry-work experts, began working together. It started its CNC journey in the mid-80s and has grown exponentially over the years to the point that it now has three major production centres in Italy and global representatives in all continents including Australia.

According to Davide Balducci, SCM Product Manager, the Accord 50 fxm is in ideal machine for the Australian market given its flexibility and application for different materials. He says it will meet the needs of many sectors, from design elements in wood to applications for plastic and advanced material.

It features a 5-Axis machining centre with fixed worktable and mobile gantry, designed for manufacturing complex-shaped and large-sized objects. It’s capable of producing panels, curved plywood, elements in solid wood, plastic, composites, resins, light alloys, prototyping, modelling and molds.

www.scmgroup.com/en_AU ■