The modular housing solution, System P4, designed by US-based Waypaver, provides ‘off-the-shelf’ automated house manufacturing.

Better known for their car factory automation, KUKA, a German manufacturer of robotics in collaboration with Waypaver International, a modular factory consultancy, have unveiled a pre-designed automation solution to manufacture modular housing.

They’re calling it System P4, and is said to provide everything a factory owner needs for an automated modular housing operation: ready-to-go, out-of-the-box.

According to company sources, it “offers predesigned factory automation solutions to build housing with car-factory efficiency and precision.”

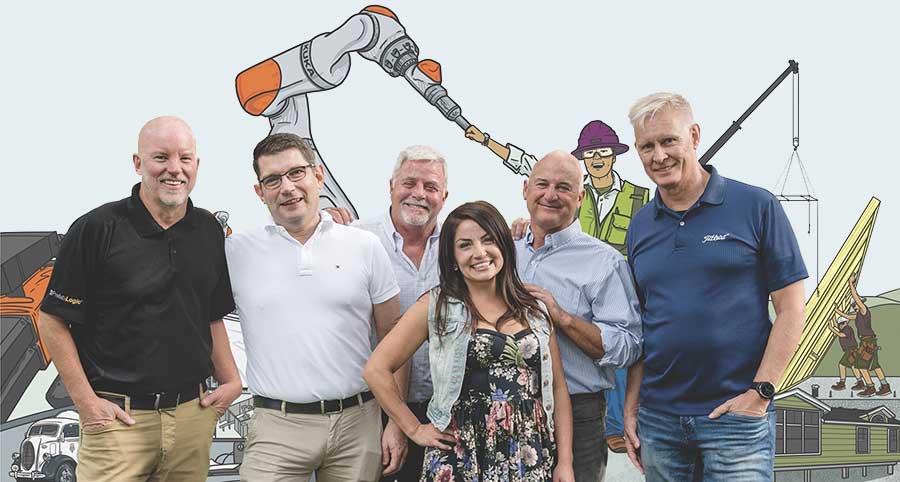

It’s backed by the P4 Housing Collective, which includes four separate companies: Waypaver, Prefab Logic, Modular Maven, and Effektiv House.

The team collectively offers a construction ecosystem of plant design, people development, preconstruction design/engineering, and products ready to be built – designed together to work together with System P4.

System P4 began with a collaboration between Rick Murdock, CEO and Founder of Waypaver, and Timo Heil, one of the CEO’s of the KUKA System Group.

The modular housing systems include plant floor layout and logistics combined with KUKA robotics automation, hardware, and integration services.

Murdock and his business partner Curtis Fletcher pioneered the use of automation in construction in what is now the highest volume automated modular factory in the western U.S. Following this success, Murdock and Fletcher were sought out by developers, factory owners, and municipalities seeking new solutions to the global housing crisis.

“Developing the world’s first automated plant of its kind forced us to make big advancements in construction engineering and manufacturing,” Murdock said.

“The goal has always been to learn and share better ways to build, advance modular construction, and make housing more attainable worldwide. Collaborating with KUKA on System P4 is a major next step because it gives future factory owners a turnkey solution based on real-world lessons learned by pioneers in both construction and automation.”

Heil – who has extensive experience in the conceptual design, planning and implementation of complex systems – adds, “KUKA has played a decisive and global role in shaping the automation of the automotive industry in its more than 100-year history. Together with the strong team around the P4 system, we will put all our know-how into a paradigm shift in the way we build homes. Because nothing less than that is needed to meet the global challenge of housing shortages. Automation closes the wide gap between construction capacity and demand, while also making construction more efficient – both in terms of cost and sustainability.”

The P4 Housing Collective

P4 Housing Collective are independent companies working collectively to standardise the modular construction process through an ecosystem of products and services designed together to work together.

P4 is an abbreviation of the four elements, including:

Plants: automation, robotics, software, integration, facility design and operational consulting led by Waypaver International.

See: https://www.waypaverintl.com

People: Factory startup culture programs, modern office design, and industry innovation consulting led by Modular Maven.

See: https://www.modularmaven.com

Precon (preconstruction): data-driven preconstruction, digital twin technology, experienced project design and logistics team led by Prefab Logic.

See: https://www.prefablogic.com

Products: off-the-shelf plans pre-vetted for automation, constructability, and optimized materials supply chain led by Effektiv House.

See: https://www.effektivhouse.com