Sign up to the Built Offsite Newsletter

PEIKKO GROUP IS A LEADING GLOBAL SUPPLIER OF SLIM FLOOR STRUCTURES AND CONNECTION TECHNOLOGY FOR PRECAST AND CAST-IN-SITU APPLICATIONS.

Trent Davis, Managing Director, Peikko Australia, confirms Peikko’s innovative solutions offer a faster, safer, more sustainable and more efficient way to design and build.

“Peikko aims to change the construction industry to be more efficient and sustainable. We are the global forerunner in slim floor structures, wind energy applications, and connection technology for precast and cast-in-situ solutions.”

“Investors and contractors can enjoy the economic benefits offered by Peikko’s product offering, by shortening the project period, saving labour costs and reducing workload. In addition, Peikko’s technical efforts in working with circular economy methodologies will help reduce the operational cost of the building and contribute to sustainability outcomes.”

“Investors and contractors can enjoy the economic benefits offered by Peikko’s product offering, by shortening the project period, saving labour costs and reducing workload. In addition, Peikko’s technical efforts in working with circular economy methodologies will help reduce the operational cost of the building and contribute to sustainability outcomes.”

Trent Davis, Managing Director, Peikko Australia.

“For designers, Peikko provides a full suite of design tools. For construction companies, Peikko in-house design team will provide detail connection design with guarantee on safety. For precasters, Peikko will provide technical support, and onsite instruction to ensure the quality and productivity.”

In terms of Peikko’s application for offsite construction, Davis cites two key product types:

BOLTED CONNECTIONS

“Ease and speed of erection are the biggest features with bolted connections. With bolted column connections, you can easily install columns to foundations and beams or make column-to-column connections. The beauty of a bolted, mechanical connection is that it can be done with a small crew on site and no temporary bracing is needed. As soon as the nuts are tightened, the connection is moment-resistant, and the crane can move on to the next column. Once grouted, a bolt connection is as stiff as a cast in-situ connection.”

Bolted connections locate columns accurately, speed up the erection process, minimise crane time, and enhance safety by maximising accessibility on site, says Davis.

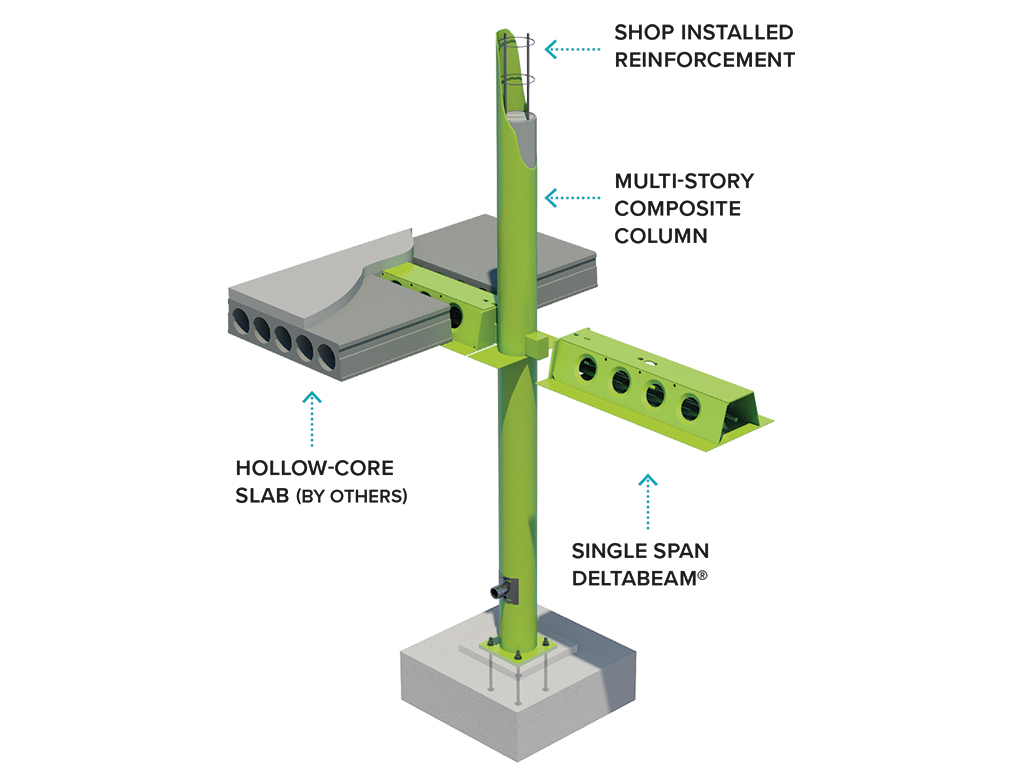

DELTABEAM FRAME STRUCTURE

The trademarked Deltabeam Slim Floor Structure enables the construction of open spaces, even with architecturally demanding shapes. Compatible with precast and cast-in-situ slabs as well as any type of columns, Deltabeam is designed to make the construction process faster and more efficient.

CASE STUDY 1: FLAGSTONE SHOPPING CENTRE, QUEENSLAND

The Flagstone Village Convenience Centre has been a part of the local community for many years. The small centre is now expanding and is set to be transformed with a 3,500 square metre Woolworths store and 21 specialty retailers providing a wide variety of products and services. The centre is positioned to meet the day to day needs of local residents, providing ease of access and shaded on-grade parking.

Peikko’s Deltabeam was chosen to provide an accelerated construction time for the client. The use of Deltabeam in conjunction with Hollowcore and precast columns has significantly reduced the onsite construction time. Project fire rating requirement was nominally 180 minutes and with Deltabeam the elimination of additional fire protection was appealing to the builder as it was one less thing that needed to be done post installation. It also provides a significant cost saving from intumescent paint.

The sloping terrain provided challenges for standard in-situ design, so the use of Peikko’s Column Shoes and Anchor Bolts in precast columns eliminated the requirement for propping and formwork and reduced the construction time considerably.

CASE STUDY 2: KEMI SNOWCASTLE, FINLAND

In February 2019, an interesting building opened to welcome its customers: an all-year-around SnowCastle. The SnowCastle is located inside a hotel building, in a separate part that is kept cold at all times while the rest of the hotel functions in normal temperatures. A key requirement of the project was that the premises should be designed as durably as possible, with structures strong enough to support 100,000 kg of ice.

“The conditions for construction were challenging since the SnowCastle hotel was built partly underground and by the sea. Also due to the cold winters in Finland, the building has to bear the harsh weather conditions and tolerate the weight of snow and ice. In addition, the SnowCastle hotel is located in a central place and had people and activities near all the time during the construction, which created more challenges. It was important to ensure that the hotel’s customers were disturbed as little as possible. For these reasons, the client decided to build with precast elements and use Peikko’s products. With bolted column connections, they were able to have a strong and durable frame that would carry the weight of the SnowCastle and face the problems with weather conditions easily. On top of that, erecting a column and building the frame was fast with precast and bolted connections so the disturbance to the customers lasted for a much shorter time.”

“Peikko has been developing offsite solutions to accelerate construction for over 50 years and they are widely used around the globe,” concludes Davis. “In Australia ‘conventional’ in-situ methods still dominate, but this is clearly changing as the need grows for faster, safer and more efficient projects.”■

“Peikko has been developing offsite solutions to accelerate construction for over 50 years and they are widely used around the globe. In Australia ‘conventional’ in-situ methods still dominate, but this is clearly changing as the need grows for faster, safer and more efficient projects.”

Trent Davis, Managing Director, Peikko Australia.