Partnership between Putzmeister and ZÜBLIN claims to have printed the world’s first 3D-printed load-bearing concrete walls.

In an intriguing advancement in construction technology, Putzmeister, a global supplier of concrete pumping technology, and ZÜBLIN, a building construction and civil engineering firm in Germany, have introduced what they claim to be the world’s first load-bearing concrete walls produced entirely by a 3D printer.

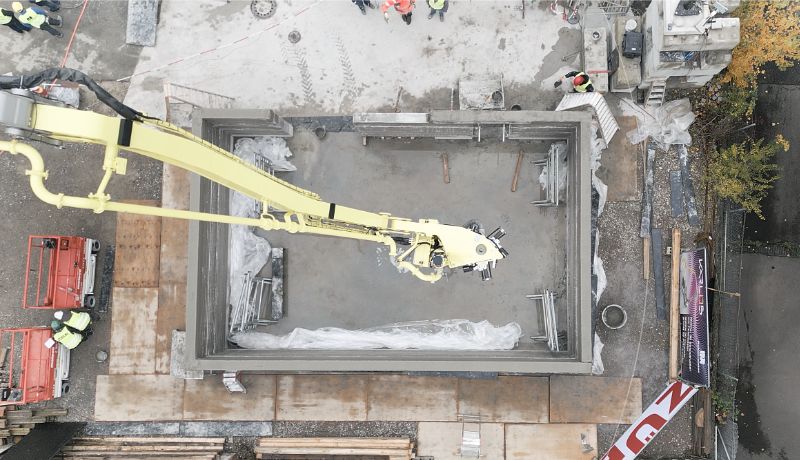

Their load-bearing walls were printed by a mobile 3D printer called KARLOS, which Putzmeister first made public in Munich in 2022.

The technology utilises a truck-mounted concrete pump equipped with an automatically controlled boom, capable of extending up to 26 metres. This boom applies concrete in multiple layers to form storey-high walls that are capable of ‘room-sealing,’ i.e., preventing the spread of fire and smoke. According to the two companies, this method not only meets but also advances current building standards.

Watch Putzmeister and ZÜBLIN print 3D load-bearing walls with a KARLOS printer

Stephan Keinath, a board member at ZÜBLIN, said on their achievement, “On our way to realising resource-saving and climate-neutral planning and construction, we are proud to have developed a highly innovative 3D printing process together with Putzmeister.” He also emphasised the integration of digital planning and advanced concrete technology as key to their load-bearing 3D printed walls.

Christoph Kaml, CEO of Putzmeister, on the significance of the KARLOS system within the company’s strategy, said, “A high degree of electrification and automation is required along the entire work process.” He pointed out that also reducing manual labour is crucial in addressing the ongoing skilled labour shortage, adding, “As a digital technology of the future, KARLOS is a central building block on the road to the construction of tomorrow.”

According to company sources, the introduction of KARLOS represents a step towards scalability in 3D concrete printing, a field previously constrained by the size limitations of gantry printers which were restricted to smaller constructions. The flexibility and range of the mobile KARLOS machine is said to promise greater scalability for large-scale projects.

Additionally, the environmental impact of this new method is said to be considerably reduced by eliminating the need for traditional formwork, producing solid wall sections in a single operation, using CO2-reduced concrete.

As the construction industry increasingly adopts digital technologies, the integration of BIM (building information modelling) and 3D printing is expected to streamline and accelerate work processes.

See: ZUBLIN