Sign up to the Built Offsite Newsletter

In collaboration with Vertex BD, Atlas Frames is carving a niche in efficient living spaces, marking a new direction for the business.

Partner content

Ricardo Ramalho and his business partner of 14 years, Robson Bortolan, journey to establish Atlas Frames, a light gauge steel modular builder located in Brendale, Queensland, began at a significant turning point. When their original business in student accommodation encountered disruptions due to the pandemic, they recognised an opportunity within the challenge.

Having devoted over nine years to cultivating their international student accommodation enterprise, Ramalho and Bortolan, and their close-knit team had already gained some familiarity with light gauge steel manufacturing through several of their projects. This modest but significant exposure gave Ramalho and Bortolan the confidence they needed to steer their business towards an entirely new direction.

“When the pandemic arrived, we jumped 100% into the light gauge steel framing business. When we started, we focused on small buildings, as we knew we wouldn’t be able to compete with more experienced, larger companies,” said Ramalho.

This fresh path has enabled the business to carve out a niche that leverages their expertise in developing small-scale accommodation and taps into the growing appeal of tiny home living, including granny flats, small modular homes, and accommodation pods. It also harnesses the advantages that light gauge steel offers to their business model, blending their developmental know-how with the burgeoning market for compact, efficient living spaces.

To further streamline their business model and maintain competitiveness, Atlas focuses exclusively on supplying the frames. This means they provide only the essential structural elements, such as walls, floor joists, and roof trusses, without any internal fit-outs. Essentially, their service is about delivering the bare bones of a structure, allowing their clients to complete it within their budget and timeframe.

A key plank of their business philosophy is to manufacture homes that are efficient, affordable and accessible to all. Interestingly, Ramalho shares a small farm with Bortolan where they are currently building a range of small houses to accommodate their families.

“What we want to do is to help people to build differently. We provide free plans and then help them to connect to the right people for each of the parts of the job. People often view house building as a DIY project, but for us, it’s about meticulous project management. We guide our clients from the initial frame to the completion of the entire project. If the clients request it, we provide not only the plan and the frames but also detailed directions for every stage of the build. We support them through the entire build,” said Ramalho.

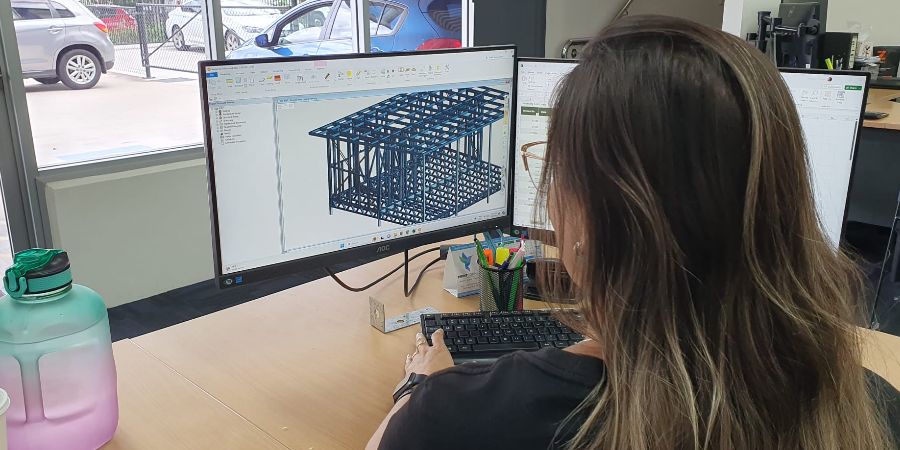

When preparing to launch Atlas Frames, Ramalho recognised the crucial need for integrating software with their LGS roll forming machines. Their extensive search led them to Vertex BD, an advanced software that streamlines construction and architectural processes, aligning seamlessly with their business model.

A key consideration in choosing Vertex BD was the availability of robust local support and expertise, ensuring not only the successful implementation of the software but also maximising its utility and efficiency in their operations. For Ramalho, adopting Vertex BD marked a significant shift. He remarked, “It was a pathway to a new way of thinking and building, focusing on small-scale, affordable housing.”

Atlas Frames’ use of Vertex BD extends beyond design and manufacturing, impacting other aspects of the business including cost management and project timelines. “It really assists us in streamlining our processes and improves our cost-effectiveness as well,” said Ramalho.

Vertex BD’s advanced engineering capabilities also enable the team to design structures that are not only aesthetically pleasing but also robust and suited to Australia’s wind regions.

“The engineering features of the software are amazing as well. By utilising the detailed reports, we’ve managed to reduce our engineering costs by 60%,” said Ramalho. Furthermore, “With tiny houses, it’s very specific. When manufacturing, you have to be precise to the millimetre. And we can only achieve this with Vertex BD.”

Looking to the future, Atlas Frames is focussed on growing their existing market. “Modular is the only way to build, and Vertex BD has been hugely supportive in assisting us to this point. We’ve also recently acquired some new features for the software which we’re also keen to explore,” concluded Ramalho.

See: https://atlasframes.com.au/

See: https://vertexaustralia.com/