3D printed D.fab admixtures method cuts CO2 emissions ‘by half’ in Copenhagen building project.

In Copenhagen, a development that’s being promoted as ‘sustainable architecture’ has been achieved with the completion of the city’s first 3D printed building made from low CO2 concrete. Spanning 72 m2, the community building, a venture by Copenhangen-based AKF in partnership with 3DCP Group, includes facilities such as a gym, a guest room, and a communal laundry area.

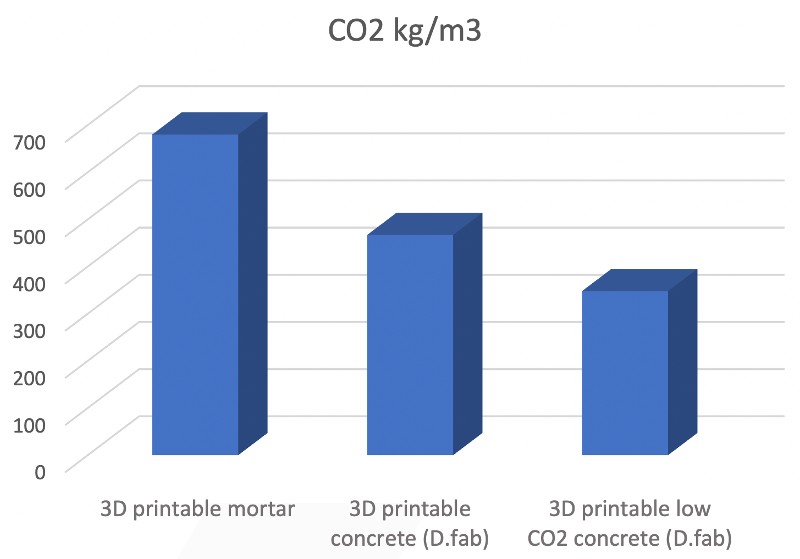

The project was printed with a novel low CO2 cement, reportedly reducing carbon emissions by 30% compared to conventional cement. This reduction is achieved through the D.fab admixtures method, developed by Cemex and COBOD, which transforms low CO2 cement mixed with locally sourced sand and gravel into a substance suitable for 3D printing. According to company sources, this technique is said to halve CO2 emissions when compared to traditional methods of 3D printing mortars.

Vibeke Lorenzen, Technical Director at AKF, commented on the broader impact of this project, saying, “3D printing opens the door to a world of possibilities, and hopefully, we can contribute to pushing the industry’s traditional construction methods.”

The entire structure was printed in five days. At last week’s launch event, Mikkel Brich, CEO of 3DCP, said, “Seeing is believing when it comes to new technology. We’re thrilled with the media turnout, showcasing the reliability and precision of this method.”

Watch the 3d printer and one of 3DCP Group’s employees in action.

Saga Architects, who were also behind the design of 3DCP Group’s first building in Denmark, aimed for a design that blended modernity with a welcoming atmosphere. They incorporated a significant amount of wood in the decorative aspects and used organic shapes in the wall construction, a technique difficult to replicate with standard construction methods.

AKF is also exploring the possibility of incorporating natural materials like clay-rich soil in future projects. They’re positioning the building as not only a major technological milestone but also a symbolic shift towards more environmentally friendly and efficient construction techniques.

See: https://cobod.com/

See: https://www.linkedin.com/company/akf-as/?originalSubdomain=dk