Sign up to the Built Offsite Newsletter

An innovative prefabricated wall timber framing system that has its origins from New Zealand has established a presence in Adelaide with a ready-to-market offering later his year.

An inspired Kiwi, Ged Finch, while studying architecture at Victoria University in Wellington in 2017 founded the reconfigurable prefabricated structural timber framing system called X-Frame. He was motivated by the desire to reduce construction waste and assist the building industry to transition to the circular economy.

After working with South Australian-based commercial innovation incubator Innovyz and Green Industries South Australia the business established its headquarters last year at the Tonsely Innovation District to commercialise the framing system.

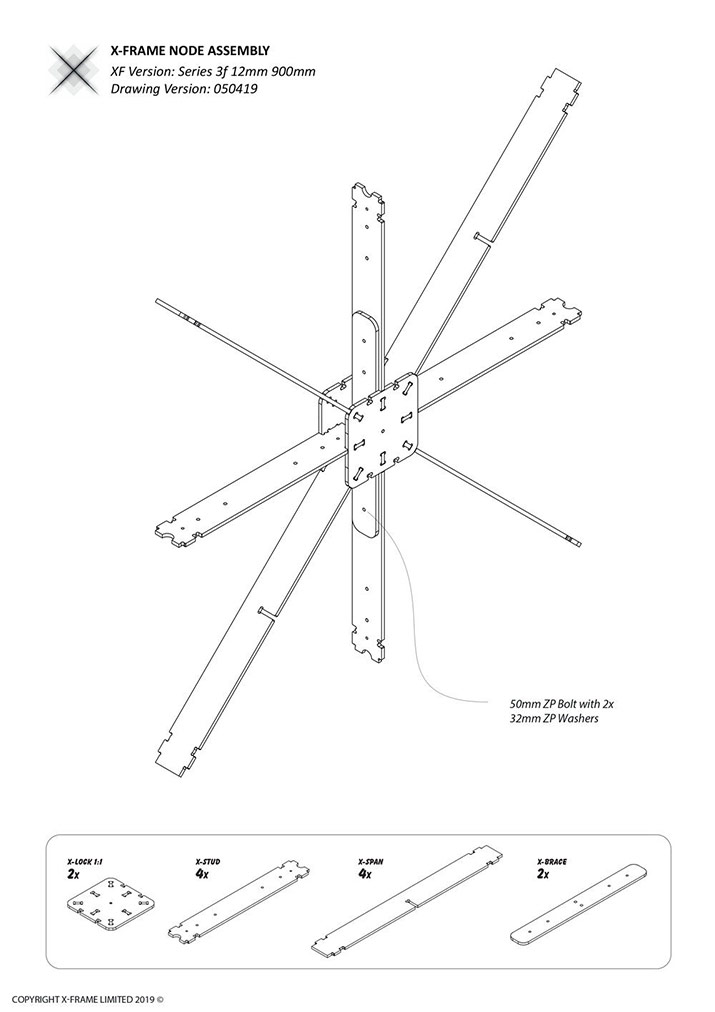

Briefly, X-Frame enables adjoining wall layers – like wall linings and claddings – to be reversibly connected through panels of plywood, which interlock and click together.

It’s based on a vision to create a modern light-weight timber frame prefabricated construction system that achieves circularity. It’s said to use 25% less material than standard timber wall framing, is carbon negative and rapidly recoverable, and has the stated ambition of eliminating end-of-life construction waste by making possible material recovery and reuse. The company says it uses “carbon negative” engineering timber material and components to develop the reusable frames.

X-Frame Australia general manager Casten Dethlefsen said the manufacturing process itself further reduced waste through a precise cutting system.

“If you look at a typical house, you’ll get a pile of sticks delivered on site that are then cut by a carpenter and put together to create the frame. In that you’ve got an enormous amount of waste that ends up in a skip,” he said.

“With X-Frame … it all comes in a kit with an instruction manual that is clipped together on site, so there’s no waste on site at all.”

Last week X-Frame announced the successful completion of its maiden capital raise of $485,000 via the Innovyz Circular Economy investors, and the company states this will enable it to capitalise on strong client interest and opportunities.

Funds raised will assist to progress design and development across multiple applications, grow strategic partnerships, secure a pipeline of projects and generate ongoing revenue. It is anticipated that following this capital raise, X-Frame will be cashflow positive within 12 months.

“X-Frame’s progress has been rapid; our initial focus has been on developing design tools, building and testing the system, forming strategic partnerships, and developing online platforms that will facilitate the seamless use of X-Frame from design to construction,” said X-Frame General Manager, Carsten Dethlefsen.

“What we’re developing is a prefabricated structural timber framing system that pretty much any architect could grab, design up what it is they want to design and deliver it in X-Frame rather than in steel frame or timber frame.

They are all very modular solutions and given COVID and the desire of a lot of companies to refit their offices to provide more separation between employees, that’s where X-Frame is ideal.

It’s also prefabricated offsite and can be brought together and stood up and then when things change again or an office needs to be reconfigured again it can be pulled apart.”

Images: X-Frame

See: https://xframe.com.au/

Click Here to return to the home page for more articles.