BATHROOM PODS: WATERTIGHT MODULAR SOLUTIONS

OFFERING REDUCED COSTS, SHORTER PROJECT TIME SCALES, MARKED GAINS IN QUALITY OUTCOMES AND HEALTH AND SAFETY BENEFITS, BATHROOM PODS PERFECTLY ENCAPSULATE SOME OF MODULAR CONSTRUCTION’S MOST COMPELLING ADVANTAGES.

One of most utilised rooms in any property, the bathroom often entails the highest number of defects and maintenance demands. Traditional bathroom builds necessitate the use of multiple trades, operating under time constraints in cramped conditions and requiring a high degree of supervision to ensure correct sequencing and quality of work.

Modular bathrooms or bathroom pods eliminate most of these issues. Particularly valuable in projects featuring a high degree of standardisation such as commercial applications, bathroom pods are built in a factory before being tested and fitted with fixtures and fittings and appliances. They are then delivered to site for installation, where they’re connected to plumbing and electrical services.

While the materials cost of bathroom pods can often be equal to site-constructed bathrooms, savings from waste and improved quality result in lower error rates and better performance in use. Many general contractors estimate the cost of managing the defects list at hundreds of dollars per bathroom on a traditional build. By contrast, utilising advanced production technology, bathroom pods promise an outcome that eliminates the ‘pain points’ of conventional construction.

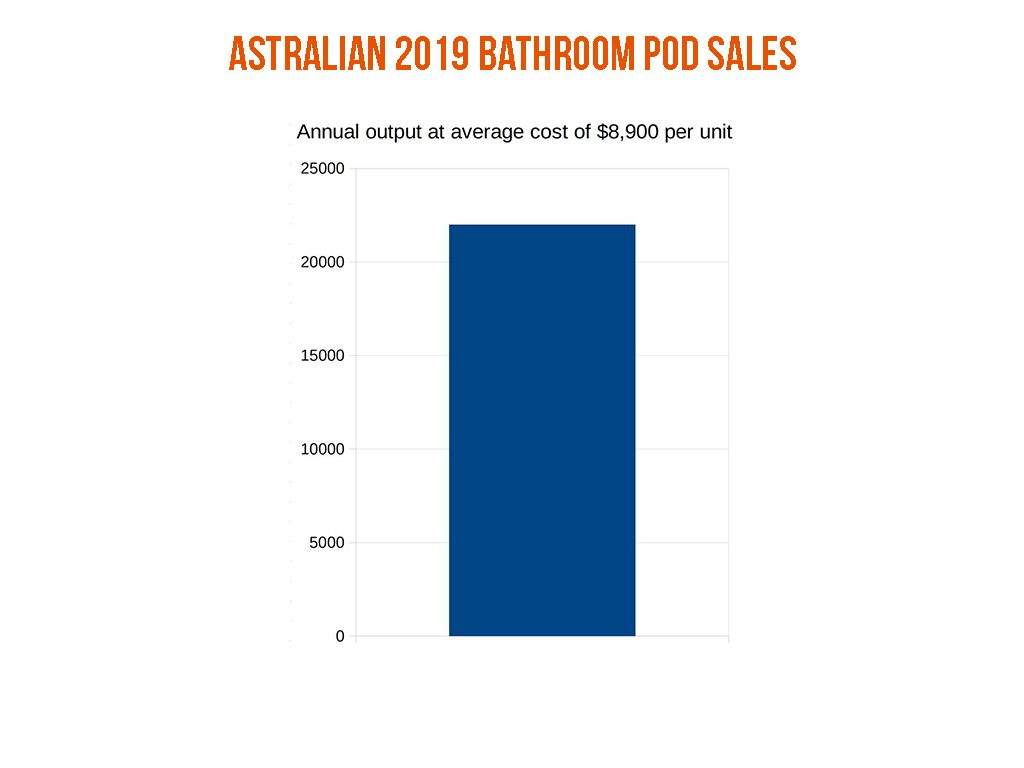

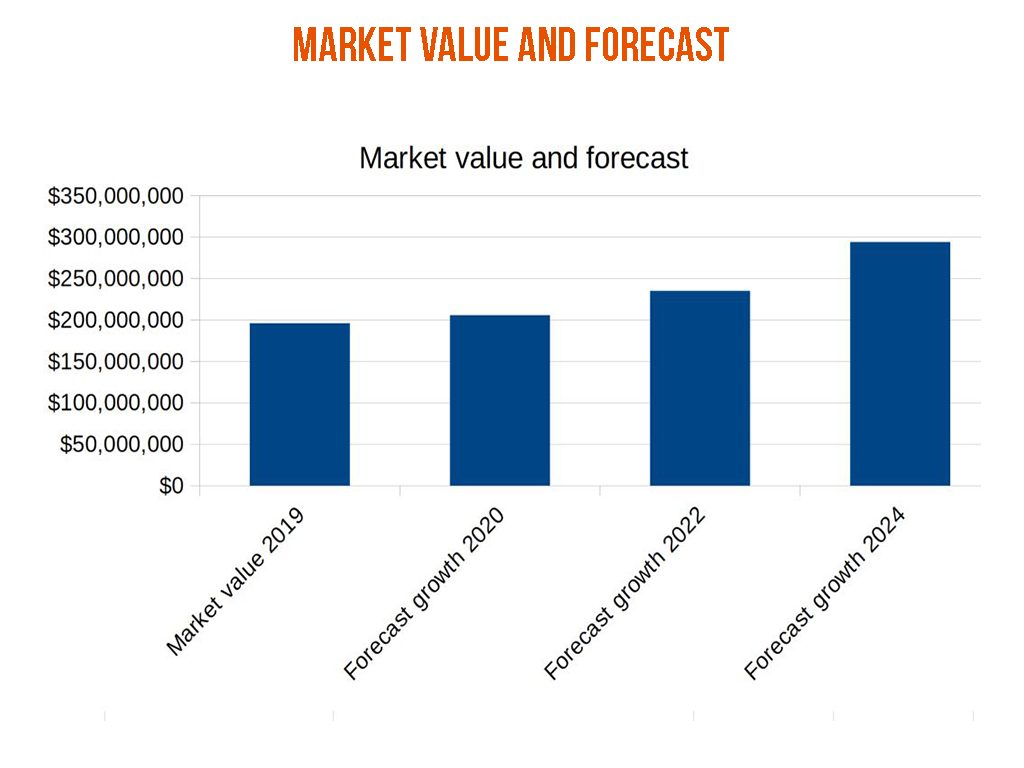

AUSTRALIAN MARKET SNAPSHOT

A number of key players have established themselves in the local bathroom pod market, including: Austruss, Buildom, Dynamic Pods, Hutchinson Builders, Interpod, Platinum Pacific Australia, Podium Pods, Puda, Schiavello and Sync (Hickory Group).

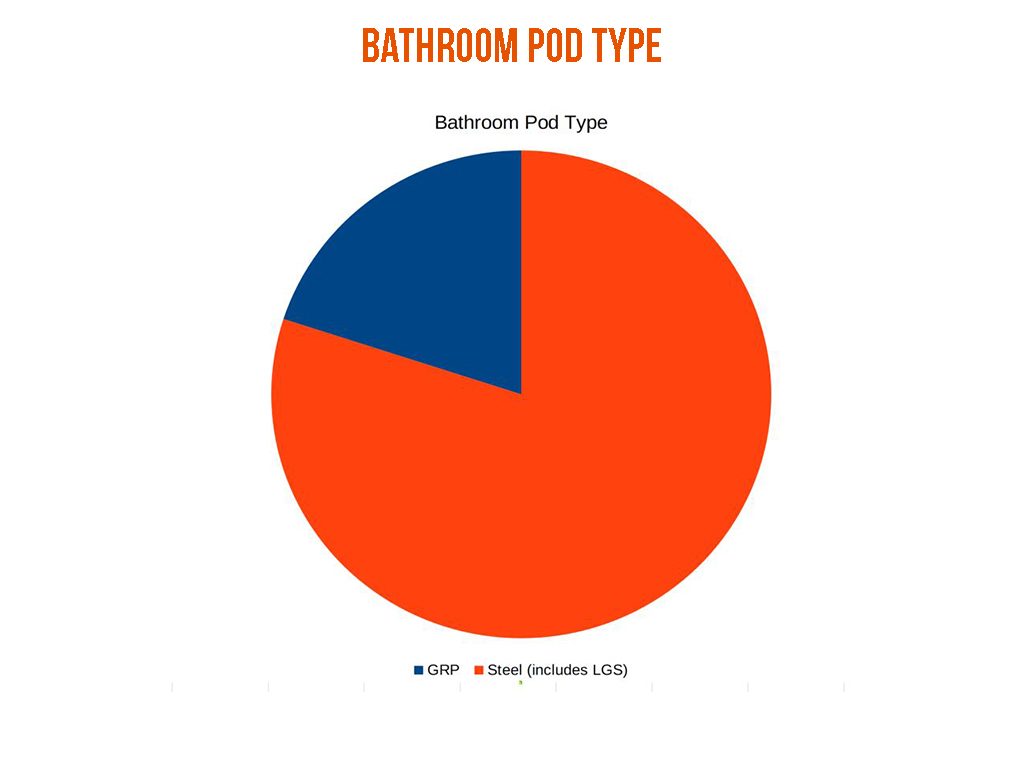

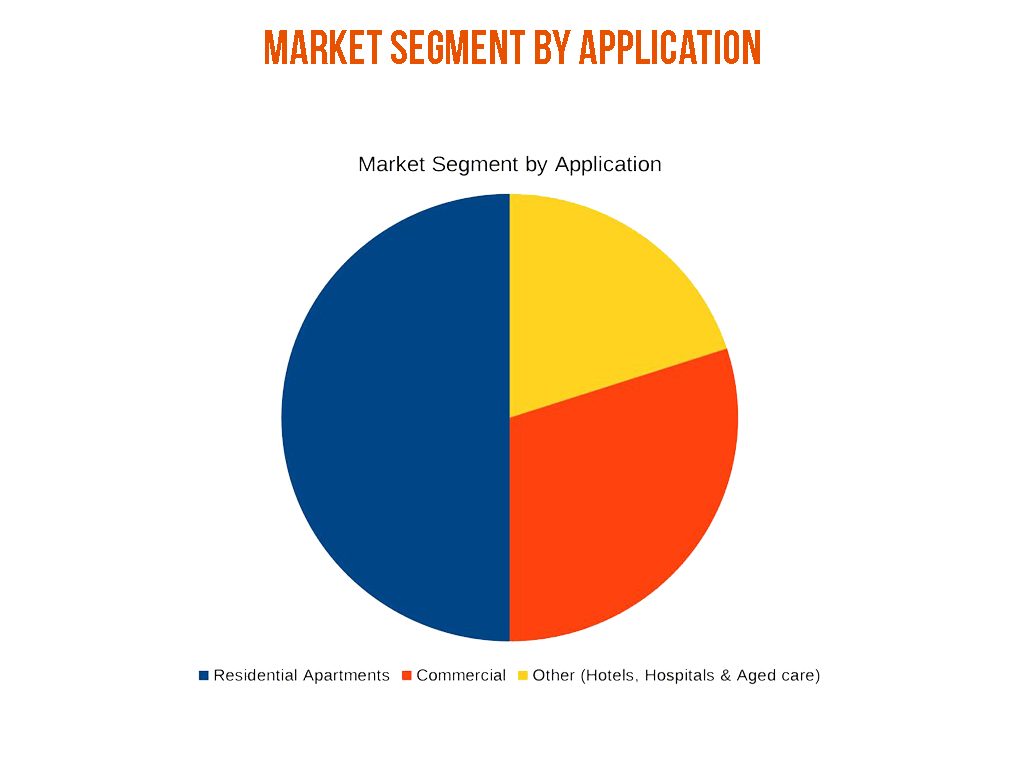

These businesses offer bathroom pods across the main applications: residential, commercial and other categories such as healthcare, educational and correctional. Each offers a unique point of difference, with a product offering typically drawn from the main bathroom pod typologies:

- GRP (glass reinforced plastic) or fibreglass bathroom pods

- Steel bathroom pods

- Other types (including concrete) of bathroom pod

CALCULATING THE COST BENEFIT OF BATHROOM PODS

A common query for bathroom pod specialists is: how much do bathroom pods cost compared to site-built?

Worth noting is that there is no such thing as a ‘standard’ bathroom pod and the scope for different specifications, from budget to high end, is broad. It’s also important to compare like for like when calculating a cost comparison.

Generally speaking, bathroom pods may often equate to site-built bathrooms on a direct cost basis. The key point of difference however is that bathroom pods are built to a much higher level of quality than those built on site. The way bathroom pods are constructed means better structural outcomes. Tiling is typically is set in such a way that prevents tiles from coming loose over time while caulk joints have a better finish, for example.

And any calculation must encompass the hidden costs of traditionally built bathrooms, which typically require more management, with a level of trade interaction much higher than other elements of the building. In addition, calculations around traditional bathrooms often omit to factor in the cost of freight and handling for heavier items such as, for example, a feature stone basin.

Bathroom pods offer advantages in the following areas:

Efficiencies: Production-line construction results in vastly reduced man hours. Installation time is significantly reduced, enabling speedier occupancy and benefiting the client. By removing bathrooms from the critical path, overall time required for a large construction project can be cut by up to 30%. The result is reduced construction loan interest, along with greater profit through an earlier opening.

Centralised purchasing: Purchasing for the lead contractor is simplified. Securing a number of trades and materials from one source reduces procurement resource time, resulting in cost savings.

Quality + consistency: Minimisation of defects is achieved through front-end design, configuration and quality control. Standardisation of factory production line methodologies means consistent repetition of quality, particularly useful in major developments, where high volumes offer resource optimisation and economies of scale. In traditional builds the defect list often entails poor tile work, chipped tubs or basins, poor blocking, and more, all of which can be “designed out” of the production line.

Waste reduction: Factory builds enable the elimination or reduction of site rubbish and waste, electricity, material handling equipment, and other resources that must be used to support the site. Using bathroom pods also minimises preopening cleaning. Factory waste material is typically less than 1.5% compared with 7%+ on a traditional construction site and recycling of waste is more reliably controlled in a factory environment than it is on site.

Safe, efficient sites: The onsite installation work required for pre-built pods is safer, quieter and cleaner than building bathrooms ‘in situ’. Industry stats estimate up to 90% fewer vehicle movements on site from using bathroom pods, reducing disruption to the site itself and the surrounding area.

NEED TO KNOW: TECHNICAL SPECIFICATIONS

Critical to a successful outcome on any project entailing bathroom pods is an understanding of the specifications for bathroom pods.*

The WaterMark Technical Specification WMTS-050: 2016 Technical Specification for plumbing and drainage products, Prefabricated bathroom modules, was originally prepared by the Joint Standards Australia/Standards New Zealand Committee WS-031, Technical Procedures for Plumbing and Drainage Products Certification.

Building on the initial specification, the WaterMark Technical Specification WMTS-050:2018 Technical Specification for plumbing and drainage products, Prefabricated modules, incorporates an amendment to expand the scope to enable variations of module types to be assessed. This Technical Specification is designed to enable product certification in accordance with the requirements of the Plumbing Code of Australia (PCA).

Among the stipulations it details are provisions to ensure standards regarding the hydrostatic strength of modules (i.e. when tested at twice the maximum operating pressure the module shall not leak or show signs of distortion, splitting, cracking, breakage or other failure.)

In addition, provisions are made where the product includes integral plumbing components, accessories or fittings that require certification, as identified in the Plumbing Code of Australia, that these shall comply with the performance requirements of the specification for that product as identified in WaterMark Technical Specification series.

Meanwhile, the specification also stipulates that documentation must include product data that identifies critical detail on factors such as delivery volume and flow rate; waste discharge flow rates and allowable temperatures; minimum operating pressure; and hydrostatic pressure loss.

Full installation instructions must also be provided with each module, including information required to enable it to be installed in accordance with the relevant clauses of AS/NZS 3500.1, AS/NZS 3500.2 and AS/NZS 3500.4.

Instructions should also include detailed step-by-step guidance; details of any special tools or training that may be required for installation; commissioning procedures and adjustments required; a troubleshooting guide and contact details for after-sales service.

Operating and maintenance instructions must also be provided and should include regular maintenance requirements; spare parts information; troubleshooting guide; and contact details for after-sales service.■

*DISCLAIMER: Advice on the specifications outlined by Built Offsite is of a compressed and general nature only, and is not a substitute for reference to the complete specifications.