10 REASONS WHY PRECAST CONCRETE IS SUSTAINABLE

Too often sustainability is interpreted as benefiting the environment only. As well as meeting the needs of the environment, sustainability must also deliver benefits to the economy and the community. Here, National Precast CEO Sarah Bachmann lists 10 reasons why precast concrete does that.

1. PRECAST CONCRETE SUPPORTS AUSTRALIAN MANUFACTURING

The precast industry uses a wide array of local materials and labour. Specifying precast supports local businesses and communities.

2. PRECAST USES LESS CONCRETE THAN IN-SITU CONCRETE

Technically advanced, high quality precast uses less concrete than an in-situ alternative. The clever designs of precast flooring systems delivers a ‘materialisation benefit’ – an up to 30 per cent saving in the volume of concrete that is used in a typical suspended floor.

3. PRECAST CONCRETE IS ENVIRONMENTALLY FRIENDLY

Most of a building’s carbon emissions are during its life. In precast’s case, the carbon that is produced during the manufacture of cement is offset, with minimal maintenance costs, lower heating and cooling costs, and the concrete reabsorbing up to 40 per cent of the carbon over the structure’s life. In addition, there’s minimal waste during manufacture and what are otherwise waste products like fly ash and slag are used. At the end of its life precast structures can be fully recycled.

4. PRECAST CONCRETE IS COMFORTABLE AND HEALTHY

Indoor air quality is critical to the health and wellbeing of families and workers alike. With precast’s high thermal mass, a building can be designed with minimal need for artificial heating and cooling. The stability of precast over its life delivers an environment free of fumes and chemicals. And there’s no need for chemical treatment up front or later on.

5. PRECAST CONCRETE SAVES MONEY

We all know building schedules are getting tighter and parallel tasks are the only way to keep ahead of the game. Ground works can commence while precast is being manufactured, just-in-time delivery eliminates double handling and subsequent trades can get in quicker. Saving time saves money, it is that simple.

6. PRECAST CONCRETE IS A SAFE, LONG TERM, LOW COST INVESTMENT

Precast concrete structures are strong, extremely tough and durable and last for years – an insurer’s dream. Precast requires almost no maintenance and can offer a substantial energy saving from its high thermal mass. And peace of mind comes from knowing that it’s tried and tested, and that it won’t burn, rot or be water damaged.

7. PRECAST CONCRETE IS HIGH QUALITY

Being manufactured in a factory-controlled environment, manufacturing precast employs advanced technologies in reuseable steel moulds, resulting in high quality products and less waste.

8. PRECAST CONCRETE ISN’T AFFECTED BY THE ELEMENTS

Everyone knows that concrete doesn’t burn. Nor does it emit toxic fumes when exposed to fire. Nor will it be damaged if exposed to cyclone or flood.

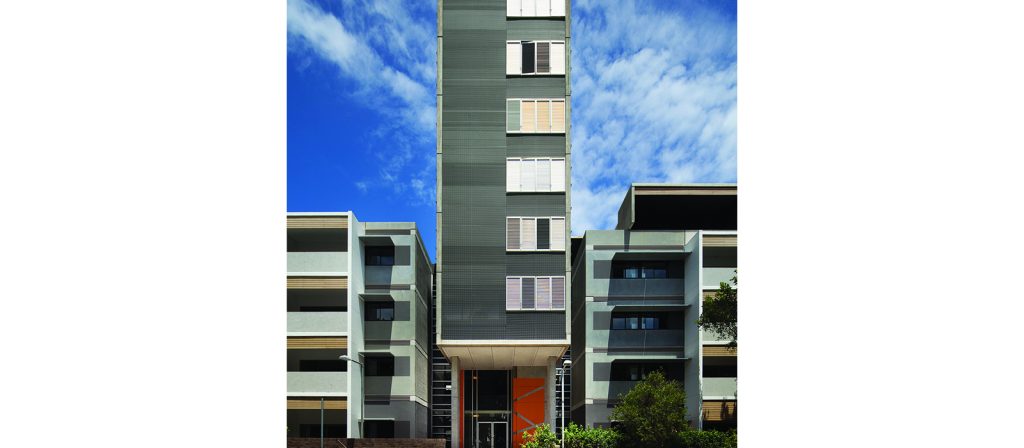

9. PRECAST CONCRETE HAS UNLIMITED DESIGN CHOICEPRECAST CONCRETE HAS UNLIMITED DESIGN CHOICE

A degree of society’s wellbeing comes from aesthetically pleasing structures. The design flexibility offered by precast can deliver award winning results. Shapes, colours and textures can all be designed to suit.

10. PRECAST CONCRETE IS BETTER FOR FAMILIES AND WORKERS

As well as delivering safer, less cluttered construction sites for construction workers, off-site manufacture means there is less noise, dust and delivery disruption to neighbours.

Of course, when it comes to materials selection, different applications will require different materials. But precast’s track record, combined with the vast benefits it offers, makes the choice easy. To find a National Precast member who can supply your next project, visit www.nationalprecast.com.au.■

Sarah Bachmann, CEO, National Precast